Design and Engineering

Anyone can design a plastic part. But not every plastic part design can be injection molded. Anderson Moulds has the experience and skill to design a part that can be economically injection molded and maintain superior physical qualities.

Mold Making

Most of our molds are now made in Asia. When we did make molds we always had a reputation for tools that would exceed SPI class standards(from Class 104 to 101). We continue to keep that reputation with our Asian molds by upgrading every foreign mold up to our standards when they arrive at our facility. We are able to to this because we have the equiptment, personnel, and experience to build our own molds.

Anderson Moulds also stongly believes in a strenuous maintenance program for all tooling. Some companies will run a mold until it needs repair or worse, until it dies. Because we disassemble and clean all molds before producing any parts the life of your molds will far exceed industry standards. This adds cost to the part price but we believe the long term benefit is justified.

Production

Anderson Moulds maintains a fully equiped molding facilility with a mold capacity of 55 ton(4.4 ounce) to 350 ton(32 ounce). Materials we are experieced in include but are not limited to:

Nylon (glass or mineral filled, supertough, TAIC filled)

Polycarb

Acetal

UHMWPE

Polyester

TPE, TPV (Santoprene)

Flexible PVC

PE, PP, ABS, Styrene, Acrylic

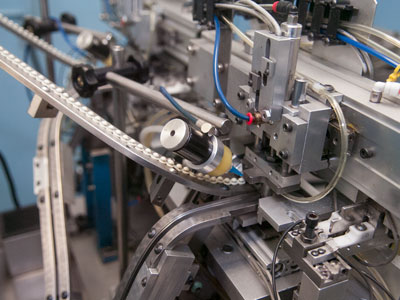

Assembly and Secondary Operations

Milling

Sonic Welding

Heat Staking (Threaded Inserts)

Custom Automated Assembly

Automated Bagging

Bottling Line

Labeling

Induction Sealing

Quality

As a custom molder each product is evaluated and a specific testing procedure is developed with the customer. These include but are not limited to:

Standard Quality Procedures

First article Part Inspection

Inprocess Part Inspection

Part sample retain

Moisture Content Testing

Lot Control Documentation

Weight Sampling

Molding Machine Process Monitoring

Custom Quality Procedures

Custom destructive testing

Dimensional Collection(calipers, micrometer,go-no-go,..etc.)

Good Manufacturing Procedures(GMP)

“It is our Goal to build a business based on the manufacturing of high quality products by high quality people who will take pride in their company.”

(taken from Anderson Moulds’ Statement of Purpose)